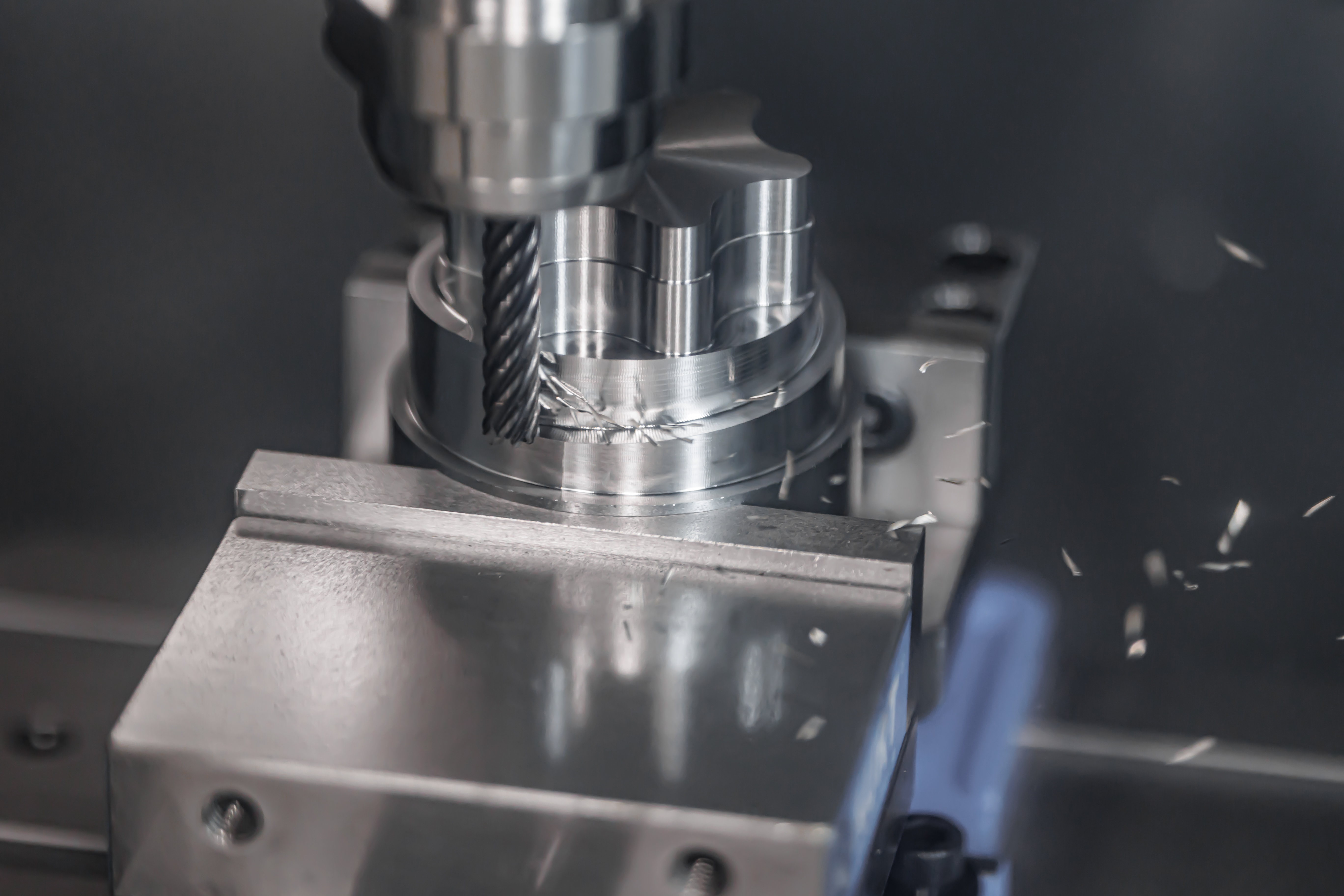

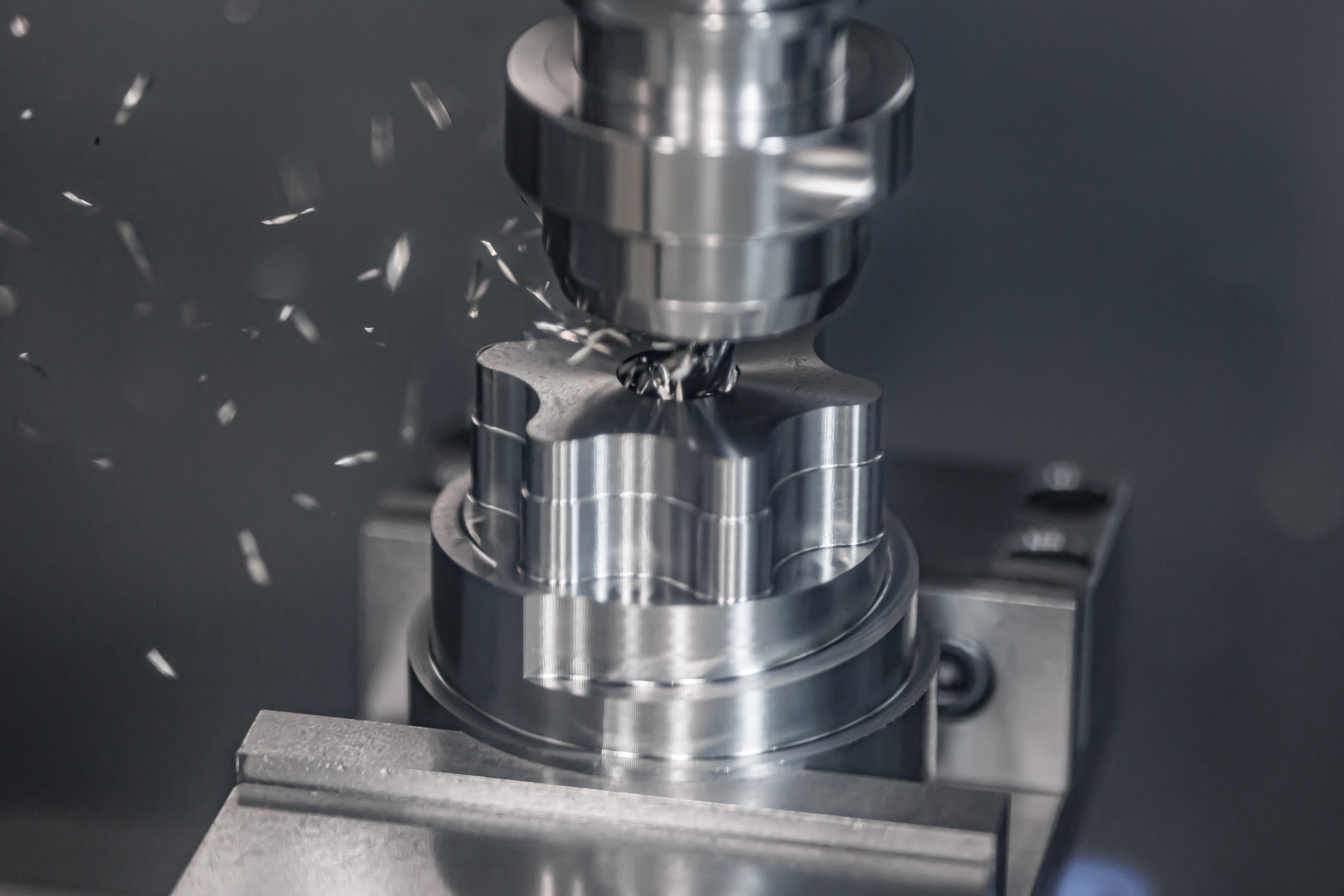

Controle dinâmico do cavaco

A série VariMill Chip Splitters de fresas de topo oferece excelente controle do cavaco, permitindo que a ferramenta funcione em profundidade de cortes mais longos, mergulhando produtivamente em compartimentos profundos em aplicações de aço, aço inoxidável e ligas de altas temperaturas.

A fresa de topo está disponível em configurações de 5 e 7 canais, ambas com passo diferencial dos canais para amortecimento de vibração.

As principais características de design da fresa de topo são pequenas estrias (divisores de cavacos) ao longo da aresta de corte para quebrar o cavaco em seções mais curtas sem reduzir o acabamento da parede. Esses cavacos curtos são mais fáceis de evacuar da área de corte, especialmente na usinagem de cavidades profundas. O recurso de divisão de cavacos também pode evitar ninhos de aves e diminuir o potencial de quebra da ferramenta.