Product Similar To:

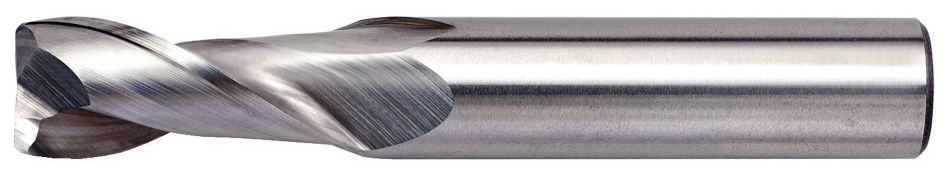

ALUFLASH • Series 3A09 • Square End • 3 Flute • Regular Length • Cylindrical Shank • Metric

ALUFLASH™ Series 3A09 • Square End • 3 Flute • Regular Length • Cylindrical Shank • Metric

Material Number6853511

ISO Catalog ID3A09M03000SZTANSI Catalog ID3A09M03000SZT

- N Non-Ferrous

Trochoidal Milling

Drilling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

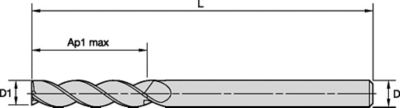

| Material Number | 6853511 |

| ISO Catalog ID | 3A09M03000SZT |

| ANSI Catalog ID | 3A09M03000SZT |

| Grade | UNCOATED |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 3 mm |

| [D1] Effective Cutting Diameter | 0.1181 in |

| [D] Adapter / Shank / Bore Diameter | 3 mm |

| [D] Adapter / Shank / Bore Diameter | 0.1181 in |

| [AP1MAX] 1st Maximum Cutting Depth | 12 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.4724 in |

| [L] Overall Length | 38 mm |

| [L] Overall Length | 1.4961 in |

| [Z] Number of Flutes | 3 |

Workpiece Materials

- Non-Ferrous

Uses and application

Trochoidal Milling

Drilling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Features and benefits

- Designed for a large variety of workpiece materials

- VariMill XTREME delivers high tool stability through several unique features like twisted end face, parabolic core and non-linear gash profile

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Application Data

| Material | 螺旋插补/坡铣 0° - 15° |  |  |  | ||||||||||||||

| UNCOATED | Recommended feed per tooth (fz = mm/z) for helical interpolation and ramping | |||||||||||||||||

| Cutting Speed | Diameter | |||||||||||||||||

| 最大深度 | Min | Start | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| mm | 2,5-4,8 | 4,6-7,6 | 5,8-9,5 | 6,9-11,4 | 9,2-15,2 | 11,5-19,0 | 13,8-22,8 | 16,1-26,6 | 18,4-30,4 | 20,7-34,2 | 23,0-38,0 | 28,8-47,5 | ||||||

| N | 1 | 1,25 x D1 | 500 | 600 | 2000 | fz | 0,022 | 0,044 | 0,055 | 0,066 | 0,088 | 0,110 | 0,132 | 0,153 | 0,176 | 0,198 | 0,220 | 0,275 |

| 2 | 1,25 x D1 | 500 | 600 | 1500 | fz | 0,020 | 0,040 | 0,048 | 0,059 | 0,079 | 0,099 | 0,119 | 0,138 | 0,158 | 0,178 | 0,198 | 0,247 | |

| 3 | 1,25 x D1 | 500 | 600 | 1500 | fz | 0,015 | 0,031 | 0,038 | 0,046 | 0,062 | 0,077 | 0,092 | 0,107 | 0,123 | 0,138 | 0,154 | 0,192 | |

| 4 | 1,25 x D1 | 400 | 450 | 750 | fz | 0,015 | 0,031 | 0,038 | 0,046 | 0,062 | 0,077 | 0,092 | 0,107 | 0,123 | 0,138 | 0,154 | 0,192 | |

| 5 | 1,25 x D1 | 250 | 400 | 1000 | fz | 0,020 | 0,040 | 0,050 | 0,059 | 0,079 | 0,099 | 0,119 | 0,138 | 0,158 | 0,178 | 0,198 | 0,247 | |

| Material | 螺旋插补/坡铣 15° - 30° |  |  |  | ||||||||||||||

| UNCOATED | Recommended feed per tooth (fz = mm/z) for helical interpolation and ramping | |||||||||||||||||

| Cutting Speed | Diameter | |||||||||||||||||

| 最大深度 | Min | Start | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| mm | 2,5-4,8 | 4,6-7,6 | 5,8-9,5 | 6,9-11,4 | 9,2-15,2 | 11,5-19,0 | 13,8-22,8 | 16,1-26,6 | 18,4-30,4 | 20,7-34,2 | 23,0-38,0 | 28,8-47,5 | ||||||

| N | 1 | 1,25 x D1 | 500 | 600 | 1600 | fz | 0,017 | 0,033 | 0,041 | 0,050 | 0,066 | 0,082 | 0,099 | 0,115 | 0,132 | 0,148 | 0,165 | 0,206 |

| 2 | 1,25 x D1 | 500 | 600 | 1200 | fz | 0,015 | 0,030 | 0,036 | 0,045 | 0,059 | 0,074 | 0,089 | 0,104 | 0,119 | 0,134 | 0,148 | 0,185 | |

| 3 | 1,25 x D1 | 500 | 600 | 1200 | fz | 0,012 | 0,023 | 0,029 | 0,035 | 0,046 | 0,058 | 0,069 | 0,080 | 0,092 | 0,104 | 0,115 | 0,144 | |

| 4 | 1,25 x D1 | 400 | 450 | 600 | fz | 0,012 | 0,023 | 0,029 | 0,035 | 0,046 | 0,058 | 0,069 | 0,080 | 0,092 | 0,104 | 0,115 | 0,144 | |

| 5 | 1,25 x D1 | 250 | 400 | 800 | fz | 0,015 | 0,030 | 0,038 | 0,045 | 0,059 | 0,074 | 0,089 | 0,104 | 0,119 | 0,134 | 0,148 | 0,185 | |

| Material | 螺旋插补/坡铣 30° - 45° |  |  |  | ||||||||||||||

| UNCOATED | Recommended feed per tooth (fz = mm/z) for helical interpolation and ramping | |||||||||||||||||

| Cutting Speed | Diameter | |||||||||||||||||

| 最大深度 | Min | Start | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| mm | 2,5-4,8 | 4,6-7,6 | 5,8-9,5 | 6,9-11,4 | 9,2-15,2 | 11,5-19,0 | 13,8-22,8 | 16,1-26,6 | 18,4-30,4 | 20,7-34,2 | 23,0-38,0 | 28,8-47,5 | ||||||

| N | 1 | 1,25 x D1 | 420 | 500 | 800 | fz | 0,013 | 0,026 | 0,033 | 0,040 | 0,053 | 0,066 | 0,079 | 0,092 | 0,106 | 0,119 | 0,132 | 0,165 |

| 2 | 1,25 x D1 | 420 | 500 | 800 | fz | 0,012 | 0,024 | 0,029 | 0,036 | 0,048 | 0,059 | 0,071 | 0,083 | 0,095 | 0,107 | 0,119 | 0,148 | |

| 3 | 1,25 x D1 | 420 | 500 | 800 | fz | 0,009 | 0,018 | 0,023 | 0,028 | 0,037 | 0,046 | 0,055 | 0,064 | 0,074 | 0,083 | 0,092 | 0,115 | |

| 4 | 1,25 x D1 | 340 | 380 | 450 | fz | 0,009 | 0,018 | 0,023 | 0,028 | 0,037 | 0,046 | 0,055 | 0,064 | 0,074 | 0,083 | 0,092 | 0,115 | |

| 5 | 1,25 x D1 | 210 | 340 | 600 | fz | 0,012 | 0,024 | 0,030 | 0,036 | 0,048 | 0,059 | 0,071 | 0,083 | 0,095 | 0,107 | 0,119 | 0,148 | |

| Material |  |  |  | |||||||||||||||||

| Plunging/Drilling | UNCOATED | Recommended feed per revolution (fn =mm/rev) for plunging 3-flute end mills | ||||||||||||||||||

| Cutting Speed | D1 | |||||||||||||||||||

| Max Depth | Applicable | Coolant | Min | Start | Max | mm | 2,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| N | 1 | 1,5 x D | Required | 120 | 260 | 400 | fn | 0,056 | 0,084 | 0,095 | 0,105 | 0,112 | 0,140 | 0,154 | 0,165 | 0,175 | 0,186 | 0,196 | 0,210 | |

| 2 | 1,5 x D | Required | 120 | 250 | 280 | fn | 0,056 | 0,084 | 0,095 | 0,105 | 0,112 | 0,140 | 0,154 | 0,165 | 0,175 | 0,186 | 0,196 | 0,210 | ||

| 3 | 1,5 x D | Required | 100 | 200 | 260 | fn | 0,056 | 0,084 | 0,095 | 0,105 | 0,112 | 0,140 | 0,154 | 0,165 | 0,175 | 0,186 | 0,196 | 0,210 | ||

| 4 | 1 x D | Required | 60 | 150 | 260 | fn | 0,042 | 0,056 | 0,070 | 0,084 | 0,098 | 0,112 | 0,140 | 0,147 | 0,154 | 0,165 | 0,175 | 0,196 | ||

| 5 | 1,5 x D | Required | 60 | 200 | 400 | fn | 0,056 | 0,084 | 0,095 | 0,105 | 0,112 | 0,140 | 0,154 | 0,165 | 0,175 | 0,186 | 0,196 | 0,210 | ||

| Material |  |  |  | |||||||||||||||||

| Plunging/Drilling | UNCOATED | Recommended feed per revolution (fn =mm/rev) for plunging 2-flute end mills | ||||||||||||||||||

| Cutting Speed | D1 | |||||||||||||||||||

| Max Depth | Applicable | Coolant | Min | Start | Max | mm | 2,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| N | 1 | 1,5 x D | Required | 120 | 260 | 400 | fn | 0,080 | 0,120 | 0,135 | 0,150 | 0,160 | 0,200 | 0,220 | 0,235 | 0,250 | 0,265 | 0,280 | 0,300 | |

| 2 | 1,5 x D | Required | 120 | 250 | 280 | fn | 0,080 | 0,120 | 0,135 | 0,150 | 0,160 | 0,200 | 0,220 | 0,235 | 0,250 | 0,265 | 0,280 | 0,300 | ||

| 3 | 1,5 x D | Required | 100 | 200 | 260 | fn | 0,080 | 0,120 | 0,135 | 0,150 | 0,160 | 0,200 | 0,220 | 0,235 | 0,250 | 0,265 | 0,280 | 0,300 | ||

| 4 | 1 x D | Required | 60 | 150 | 260 | fn | 0,060 | 0,080 | 0,100 | 0,120 | 0,140 | 0,160 | 0,200 | 0,210 | 0,220 | 0,235 | 0,250 | 0,280 | ||

| 5 | 1,5 x D | Required | 60 | 200 | 400 | fn | 0,080 | 0,120 | 0,135 | 0,150 | 0,160 | 0,200 | 0,220 | 0,235 | 0,250 | 0,265 | 0,280 | 0,300 | ||

| Material |  |  |  | |||||||||||||||||

| Side Milling (A) and Slotting (B) | UNCOATED | Recommended feed per tooth (fz = mm/z) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||

| A | B | Cutting Speed | D1 | |||||||||||||||||

| ap | ae | ap | Min | Start | Max | mm | 2,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| N | 1 | Ap1 max | 0,5 x D1 | 1 x D | 500 | 600 | 2000 | fz | 0,022 | 0,044 | 0,055 | 0,066 | 0,088 | 0,110 | 0,132 | 0,153 | 0,176 | 0,198 | 0,220 | 0,275 |

| 2 | Ap1 max | 0,5 x D1 | 1 x D | 500 | 600 | 1500 | fz | 0,020 | 0,040 | 0,048 | 0,059 | 0,079 | 0,099 | 0,119 | 0,138 | 0,158 | 0,178 | 0,198 | 0,247 | |

| 3 | Ap1 max | 0,5 x D1 | 1 x D | 500 | 600 | 1500 | fz | 0,015 | 0,031 | 0,038 | 0,046 | 0,062 | 0,077 | 0,092 | 0,107 | 0,123 | 0,138 | 0,154 | 0,192 | |

| 4 | Ap1 max | 0,5 x D1 | 1 x D | 400 | 450 | 750 | fz | 0,015 | 0,031 | 0,038 | 0,046 | 0,062 | 0,077 | 0,092 | 0,107 | 0,123 | 0,138 | 0,154 | 0,192 | |

| 5 | Ap1 max | 0,5 x D1 | 1 x D | 250 | 400 | 1000 | fz | 0,020 | 0,040 | 0,050 | 0,059 | 0,079 | 0,099 | 0,119 | 0,138 | 0,158 | 0,178 | 0,198 | 0,247 | |

| Material |  |  |  | |||||||||||||||||

| Side Milling (A) and Slotting (B) | UNCOATED | Recommended feed per tooth (fz = mm/z) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||

| A | B | Cutting Speed | D1 | |||||||||||||||||

| ap | ae | ap | Min | Start | Max | mm | 2,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| N | 1 | Ap1 max | 0,5 x D1 | 1 x D | 500 | 600 | 2000 | fz | 0,022 | 0,044 | 0,055 | 0,066 | 0,088 | 0,110 | 0,132 | 0,153 | 0,176 | 0,198 | 0,220 | 0,275 |

| 2 | Ap1 max | 0,5 x D1 | 1 x D | 500 | 600 | 1500 | fz | 0,020 | 0,040 | 0,048 | 0,059 | 0,079 | 0,099 | 0,119 | 0,138 | 0,158 | 0,178 | 0,198 | 0,247 | |

| 3 | Ap1 max | 0,5 x D1 | 1 x D | 500 | 600 | 1500 | fz | 0,015 | 0,031 | 0,038 | 0,046 | 0,062 | 0,077 | 0,092 | 0,107 | 0,123 | 0,138 | 0,154 | 0,192 | |

| 4 | Ap1 max | 0,5 x D1 | 1 x D | 400 | 450 | 750 | fz | 0,015 | 0,031 | 0,038 | 0,046 | 0,062 | 0,077 | 0,092 | 0,107 | 0,123 | 0,138 | 0,154 | 0,192 | |

| 5 | Ap1 max | 0,5 x D1 | 1 x D | 250 | 400 | 1000 | fz | 0,020 | 0,040 | 0,050 | 0,059 | 0,079 | 0,099 | 0,119 | 0,138 | 0,158 | 0,178 | 0,198 | 0,247 | |

I have read and accepted the Terms & Conditions of use