Product Similar To:

VSM490™-15 • XNPU-ML • Light Machining

Inserts • XNPU-ML • Light Machining

Material Number5883099

ISO Catalog IDXNPU15T608ERMLANSI Catalog IDXNPU1502ERML

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

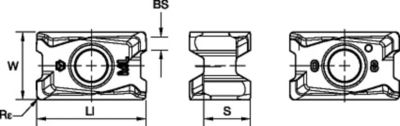

| Material Number | 5883099 |

| ISO Catalog ID | XNPU15T608ERML |

| ANSI Catalog ID | XNPU1502ERML |

| Grade | WU35PM |

| Cutting Edges per Insert | 4 |

| [LI] Insert Length | 16.1 mm |

| [LI] Insert Length | 0.634 in |

| [S] Insert Thickness | 6.88 mm |

| [S] Insert Thickness | 0.271 in |

| [W] Insert Width | 10 mm |

| [W] Insert Width | 0.394 in |

| [BS] Corner Facet Length | 1.9 mm |

| [BS] Corner Facet Length | 0.073 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.08 mm |

| Average Chip Thickness [HM] | 0.003 in |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Features and benefits

- ML geometry is the first choice for machining stainless steel

- With reduced cutting forces, this is recommended for improved wall finishing capabilities in steels

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Feeds

Recommended Starting Feeds [mm]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | 0,11 | 0,23 | 0,35 | 0,08 | 0,17 | 0,25 | 0,06 | 0,13 | 0,19 | 0,05 | 0,11 | 0,16 | 0,05 | 0,10 | 0,15 | .E..ALP |

| .E..ML | 0,17 | 0,31 | 0,46 | 0,13 | 0,23 | 0,33 | 0,09 | 0,17 | 0,25 | 0,08 | 0,15 | 0,22 | 0,08 | 0,14 | 0,20 | .E..ML |

| .S..MM | 0,22 | 0,40 | 0,64 | 0,16 | 0,29 | 0,46 | 0,12 | 0,22 | 0,34 | 0,10 | 0,19 | 0,30 | 0,10 | 0,18 | 0,28 | .S..MM |

| .S..MH | 0,23 | 0,45 | 0,74 | 0,17 | 0,33 | 0,54 | 0,13 | 0,24 | 0,40 | 0,11 | 0,21 | 0,35 | 0,10 | 0,20 | 0,32 | .S..MH |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | ||||||||||||||||

| Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| .E..ALP | .005 | .008 | .012 | .003 | .006 | .009 | .002 | .004 | .007 | .002 | .004 | .006 | .002 | .004 | .005 | .E..ALP |

| .E..ML | .007 | .012 | .018 | .005 | .009 | .013 | .004 | .006 | .010 | .003 | .006 | .008 | .003 | .005 | .008 | .E..ML |

| .S..MM | .008 | .015 | .024 | .006 | .011 | .017 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .007 | .010 | .S..MM |

| .S..MH | .009 | .017 | .028 | .006 | .012 | .020 | .005 | .009 | .015 | .004 | .008 | .013 | .004 | .007 | .012 | .S..MH |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]*

| Material Group | WK15CM | WK15PM | WK20PM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU35PM | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 295 | 260 | 245 | – | – | – | 260 | 230 | 215 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 250 | 215 | 180 | – | – | – | 220 | 190 | 160 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 230 | 195 | 160 | – | – | – | 200 | 170 | 140 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 225 | 185 | 150 | 190 | 175 | 160 | 205 | 170 | 135 | – | – | – | 180 | 150 | 120 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 170 | 150 | 260 | 230 | 210 | 170 | 155 | 135 | 170 | 145 | 120 | 150 | 135 | 120 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 150 | 115 | 90 | 150 | 110 | 80 | 130 | 100 | 80 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | 195 | 170 | 155 | 210 | 170 | 140 | 170 | 150 | 135 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | 175 | 150 | 125 | 180 | 145 | 120 | 155 | 130 | 110 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | 130 | 115 | 90 | 145 | 110 | 85 | 115 | 100 | 80 | |

| K | 1 | 420 | 385 | 340 | 270 | 245 | 215 | 360 | 290 | 245 | – | – | – | 230 | 205 | 185 | 295 | 265 | 240 | – | – | – | – | – | – | – | – | – |

| 2 | 335 | 295 | 275 | 210 | 190 | 175 | 280 | 230 | 195 | – | – | – | 180 | 160 | 150 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – | |

| 3 | 280 | 250 | 230 | 175 | 160 | 145 | 210 | 175 | 140 | – | – | – | 150 | 135 | 120 | 195 | 175 | 160 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 50 | 30 | 60 | 45 | 30 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]*

| Material Group | WK15CM | WK15PM | WK20PM | WN25PM | WP25PM | WP35CM | WP40PM | WS40PM | WU35PM | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 1085 | 935 | 885 | 1495 | 1295 | 1215 | 970 | 855 | 805 | – | – | – | 855 | 755 | 705 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 900 | 785 | 655 | 920 | 835 | 755 | 820 | 705 | 590 | – | – | – | 720 | 625 | 525 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 835 | 705 | 575 | 835 | 755 | 675 | 755 | 640 | 525 | – | – | – | 655 | 560 | 460 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 740 | 605 | 490 | 625 | 575 | 525 | 675 | 560 | 445 | – | – | – | 590 | 490 | 395 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 605 | 560 | 490 | 855 | 755 | 690 | 560 | 510 | 445 | 560 | 475 | 395 | 490 | 445 | 395 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 540 | 410 | 330 | 525 | 445 | 360 | 490 | 375 | 295 | 490 | 360 | 260 | 425 | 330 | 260 | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 675 | 590 | 540 | 675 | 605 | 510 | 640 | 560 | 510 | 690 | 560 | 460 | 560 | 490 | 445 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 605 | 525 | 425 | 605 | 525 | 460 | 575 | 490 | 410 | 590 | 475 | 395 | 510 | 425 | 360 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | 425 | 375 | 295 | 475 | 360 | 280 | 375 | 330 | 260 | |

| K | 1 | 1380 | 1265 | 1115 | 885 | 805 | 705 | 1180 | 950 | 805 | – | – | – | 755 | 675 | 605 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| 2 | 1100 | 970 | 900 | 690 | 625 | 575 | 920 | 755 | 640 | – | – | – | 590 | 525 | 490 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | |

| 3 | 920 | 820 | 755 | 575 | 525 | 475 | 690 | 575 | 460 | – | – | – | 490 | 445 | 395 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | 115 | 100 | 80 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 130 | 115 | 80 | – | – | – | 130 | 115 | 100 | 130 | 115 | 80 | 115 | 100 | 80 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 165 | 130 | 80 | – | – | – | 165 | 130 | 100 | 165 | 130 | 80 | 150 | 115 | 80 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | 230 | 165 | 115 | – | – | – | 215 | 165 | 115 | 195 | 165 | 100 | 195 | 150 | 100 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

Insert Selection Guide

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | XNGU-ML | WP40PM | XNPU-MM | WP40PM | XNPU-MM | WP40PM |

| P3–P4 | XNGU-ML | WP40PM | XNPU-MM | WP40PM | XNPU-MM | WP40PM |

| P5–P6 | XNGU-MM | WP25PM | XNPU-MM | WP35CM | XNPU-MM | WP40PM |

| M1–M2 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| M3 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| K1–K2 | XNPU-MM | WK15PM | XNGU-MH | WK15CM | XNGU-MH | WK15CM |

| K3 | XNPU-MM | WK15PM | XNGU-MH | WP35CM | XNGU-MH | WP35CM |

| N1–N2 | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM |

| N3 | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM | XNGU-ALP | WN25PM |

| S1–S2 | XNGU-ML | WP25PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| S3 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| S4 | XNGU-ML | WS40PM | XNGU-ML | WS40PM | XNPU-MM | WS40PM |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use