Product Similar To:

TOP DRILL Deep Hole • 20 x D • TDD106 • 2 Flute

TDD106 • 20 x D • Metric

Material Number3899770

ISO Catalog IDTDD106Z08500ANSI Catalog IDTDD106Z08500

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling

Drilling: Stacked Plates

Drilling - Through Coolant

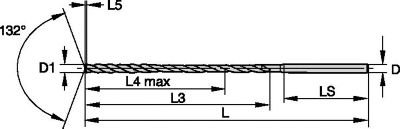

Tool Dimensions: 2flute/4margin/coolant

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3899770 |

| ISO Catalog ID | TDD106Z08500 |

| ANSI Catalog ID | TDD106Z08500 |

| Grade | WU20PD |

| [D1] Drill Diameter M | 8.5 mm |

| [D1] Drill Diameter M | 0.3346 in |

| [D] Adapter / Shank / Bore Diameter | 9 mm |

| [D] Adapter / Shank / Bore Diameter | 0.3543 in |

| [L3] Flute Length | 196 mm |

| [L3] Flute Length | 7.7165 in |

| [L4] Maximum Drilling Depth | 177 mm |

| [L4] Maximum Drilling Depth | 6.9685 in |

| [L5] Drill Point Length | 1.788 mm |

| [L5] Drill Point Length | 0.0704 in |

| [LS] Shank Length | 42 mm |

| [LS] Shank Length | 1.6535 in |

| [L] Overall Length | 245 mm |

| [L] Overall Length | 9.6457 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Drilling

Drilling: Stacked Plates

Drilling - Through Coolant

Tool Dimensions: 2flute/4margin/coolant

Grades

WU20PD

Composition: With a multilayered PVD TiN-TiAlN coating, a high-quality, sub-micron, carbide substrate and a state-of-the-art surface condition, this grade gives the highest level of wear resistance at high cutting speeds.

Application: First choice for alloyed and high-alloyed steels and cast irons. A state-of-the-art surface condition enables superior chip evacuation even when MQL is applied.

Features and benefits

- Standard items listed. Additional diameters and lengths made to order.

- For information about Custom Solutions, such as multi-step drills, see page [REFERENCE].

- For information about Reconditioning Services, see page [REFERENCE].

- For best results, please use recommended pilot drill as indicated below.

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Application Data

| Metric | |||

| tolerance | |||

| nominal size range | D1 tolerance | D1 tolerance | D tolerance h6 |

| 0,000/-0,012 | 0,000/-0,008 | ||

| 0,000/-0,015 | 0,000/-0,009 | ||

| 0,000/-0,018 | 0,000/-0,011 | ||

Application Data • TDD Series • WU20PD™ • Through Coolant • Metric

| Inch | |||

| tolerance | |||

| D1 | D1 tolerance m7 | D | D tolerance h6 |

| .0000/-.0005 | .0000/-.0003 | ||

| .0000/-.0006 | .0000/-.0004 | ||

| .0000/-.0007 | .0000/-.0004 | ||

I have read and accepted the Terms & Conditions of use