Product Similar To:

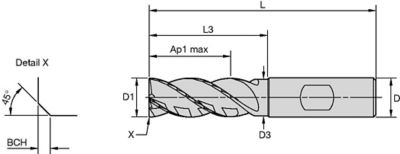

VariMill™ XTREME™ • Series 4XNE • Chamfered • 4 Flute • Necked • Weldon® Shank • Metric

Series 4XNE • Chamfered • 4 Flutes • Necked • Weldon® Shank • Metric

Material Number6830473

ISO Catalog ID4XNEM20007CCWANSI Catalog ID4XNEM20007CCW

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Drilling

Helical Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Plunge Milling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6830473 |

| ISO Catalog ID | 4XNEM20007CCW |

| ANSI Catalog ID | 4XNEM20007CCW |

| Grade | WS15PE |

| Adapter Style Machine Side | Weldon |

| [D1] Effective Cutting Diameter | 20 mm |

| [D1] Effective Cutting Diameter | 0.7874 in |

| [D] Adapter / Shank / Bore Diameter | 20 mm |

| [D] Adapter / Shank / Bore Diameter | 0.7874 in |

| [D3] Neck Diameter | 18.8 mm |

| [D3] Neck Diameter | 0.7402 in |

| [AP1MAX] 1st Maximum Cutting Depth | 40 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.5748 in |

| [L3] Usable Length | 60 mm |

| [L3] Usable Length | 2.3622 in |

| [L] Overall Length | 115 mm |

| [L] Overall Length | 4.5276 in |

| [BCH] Corner Chamfer Width | 0.3 mm |

| [BCH] Corner Chamfer Width | 0.0118 in |

| [Z] Number of Flutes | 4 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Trochoidal Milling

Drilling

Helical Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Plunge Milling

Grades

WS15PE

PVD-coated carbide grade with optimized chemistry and process for increased wear resistance. State-of-the-art, post-coat treatment reduces friction and helps manage heat when cutting super alloys.

Features and benefits

- Covers a broad range of applications including helical interpolation, ramping and plunging

- Designed for use on a large variety of workpiece materials

- Delivers high tool stability through several unique features including twisted end face, parabolic core, non-linear gash profile

- Four asymmetrical divided flutes and a variable helix help reduce vibrations

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Application Data

| Material |  |  |  | |||||||||||||||||

| Side Milling (A) and Slotting (B) | WS15PE | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||

| A | B | Cutting Speed | D1 | |||||||||||||||||

| ap | ae | ap | Min | Start | Max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| P | 0 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 150 | 175 | 200 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 1 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 150 | 175 | 200 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 2 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 140 | 165 | 190 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 3 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 120 | 140 | 160 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 4 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 90 | 120 | 150 | fz | 0,018 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 | |

| 5 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 60 | 80 | 100 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 6 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 50 | 65 | 75 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| M | 1 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 90 | 100 | 115 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 60 | 70 | 80 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D1 | 0,5 x D1 | 1,0 x D1 | 60 | 65 | 70 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| K | 1 | 1,5 x D1 | 0,5 x D1 | 1,0 x D1 | 120 | 135 | 150 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 2 | 1,5 x D1 | 0,5 x D1 | 1,0 x D1 | 110 | 125 | 140 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 3 | 1,5 x D1 | 0,5 x D1 | 1,0 x D1 | 110 | 120 | 130 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| S | 1 | 1,5 x D1 | 0,5 x D1 | 0,75 x D1 | 50 | 70 | 90 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,061 | 0,070 | 0,079 | 0,087 | 0,095 | 0,101 | 0,114 |

| 2 | 1,5 x D1 | 0,5 x D1 | 0,75 x D1 | 50 | 65 | 80 | fz | 0,009 | 0,013 | 0,016 | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,054 | 0,061 | |

| 3 | 1,5 x D1 | 0,5 x D1 | 0,5 x D1 | 25 | 30 | 40 | fz | 0,009 | 0,013 | 0,016 | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,054 | 0,061 | |

| 4 | 1,5 x D1 | 0,5 x D1 | 1,25 x D1 | 50 | 55 | 60 | fz | 0,011 | 0,016 | 0,021 | 0,026 | 0,037 | 0,045 | 0,052 | 0,058 | 0,064 | 0,069 | 0,074 | 0,084 | |

| H | 1 | 1,5 x D1 | 0,5 x D1 | 1,0 x D1 | 80 | 110 | 140 | fz | 0,018 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 |

| 2 | 1,5 x D1 | 0,5 x D1 | 1,0 x D1 | 70 | 90 | 120 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| NOTE: See page B92 for more information on VARIMILL™ XTREME™ adjustment factors for feed calculations. | ||||||||||||||||||||

| Helical Interpolation/Ramping | ||||||||||||||||||

|  | Recommended feed per tooth (fz = mm/z) for Helical Interpolation and Ramping | ||||||||||||||||

| WS15PE | Diameter | |||||||||||||||||

| Cutting Speed | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | |||||

| Material | Max Depth | min | Start | max | min-max | 3,5-5,7 | 4,6-7,6 | 5,8-9,5 | 6,9-11,4 | 9,2-15,2 | 11,5-19,0 | 13,8-22,8 | 16,1-26,6 | 18,4-30,4 | 20,7-34,2 | 23,0-38,0 | 28,8-47,5 | |

| P | 0 | 1,25 x D1 | 150 | 175 | 200 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 1 | 1,25 x D1 | 150 | 175 | 200 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 2 | 1,25 x D1 | 140 | 165 | 190 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 3 | 1,25 x D1 | 120 | 140 | 160 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 4 | 1,25 x D1 | 90 | 120 | 150 | fz | 0,018 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 | |

| 5 | 1,25 x D1 | 60 | 80 | 100 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 6 | 1,25 x D1 | 50 | 65 | 75 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| M | 1 | 1,25 x D1 | 90 | 100 | 115 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,25 x D1 | 60 | 70 | 80 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,0 x D1 | 60 | 65 | 70 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| K | 1 | 1,0 x D1 | 120 | 135 | 150 | fz | 0,023 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 2 | 1,0 x D1 | 110 | 125 | 140 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 3 | 1,0 x D1 | 110 | 120 | 130 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| S | 1 | 0,75 x D1 | 50 | 70 | 90 | fz | 0,019 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 0,75 x D1 | 50 | 65 | 80 | fz | 0,016 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 0,5 x D1 | 25 | 30 | 40 | fz | 0,010 | 0,014 | 0,018 | 0,021 | 0,029 | 0,035 | 0,041 | 0,046 | 0,051 | 0,055 | 0,059 | 0,067 | |

| 4 | 1,25 x D1 | 50 | 55 | 60 | fz | 0,013 | 0,017 | 0,023 | 0,028 | 0,040 | 0,049 | 0,057 | 0,064 | 0,071 | 0,076 | 0,082 | 0,092 | |

| H | 1 | 1,0 x D1 | 80 | 110 | 140 | fz | 0,018 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 |

| 2 | 1,0 x D1 | 70 | 90 | 120 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| Helical Interpolation/Ramping | ||||||||||||||||||

|  | Recommended feed per tooth (fz = mm/z) for Helical Interpolation and Ramping | ||||||||||||||||

| WS15PE | Diameter | |||||||||||||||||

| Cutting Speed | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | |||||

| Material | Max Depth | min | Start | max | min-max | 3,5-5,7 | 4,6-7,6 | 5,8-9,5 | 6,9-11,4 | 9,2-15,2 | 11,5-19,0 | 13,8-22,8 | 16,1-26,6 | 18,4-30,4 | 20,7-34,2 | 23,0-38,0 | 28,8-47,5 | |

| P | 0 | 1.25 x D1 | 150 | 165 | 175 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,059 | 0,068 | 0,076 | 0,083 | 0,089 | 0,094 | 0,102 |

| 1 | 1.25 x D1 | 150 | 165 | 175 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,059 | 0,068 | 0,076 | 0,083 | 0,089 | 0,094 | 0,102 | |

| 2 | 1.25 x D1 | 140 | 155 | 165 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,059 | 0,068 | 0,076 | 0,083 | 0,089 | 0,094 | 0,102 | |

| 3 | 1.25 x D1 | 120 | 130 | 140 | fz | 0,014 | 0,019 | 0,025 | 0,030 | 0,041 | 0,050 | 0,058 | 0,065 | 0,072 | 0,078 | 0,083 | 0,094 | |

| 4 | 1.25 x D1 | 90 | 105 | 120 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,045 | 0,051 | 0,058 | 0,063 | 0,068 | 0,073 | 0,080 | |

| 5 | 1.25 x D1 | 60 | 70 | 80 | fz | 0,012 | 0,016 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 | |

| 6 | 1.25 x D1 | 50 | 55 | 65 | fz | 0,010 | 0,013 | 0,017 | 0,020 | 0,028 | 0,033 | 0,038 | 0,043 | 0,047 | 0,050 | 0,053 | 0,059 | |

| M | 1 | 1.25 x D1 | 90 | 95 | 100 | fz | 0,014 | 0,019 | 0,025 | 0,030 | 0,041 | 0,050 | 0,058 | 0,065 | 0,072 | 0,078 | 0,083 | 0,094 |

| 2 | 1.25 x D1 | 60 | 65 | 70 | fz | 0,012 | 0,016 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 | |

| 3 | 1.0 x D1 | 60 | 62 | 65 | fz | 0,010 | 0,013 | 0,017 | 0,020 | 0,028 | 0,033 | 0,038 | 0,043 | 0,047 | 0,050 | 0,053 | 0,059 | |

| K | 1 | 1.0 x D1 | 120 | 130 | 135 | fz | 0,017 | 0,023 | 0,030 | 0,036 | 0,050 | 0,059 | 0,068 | 0,076 | 0,083 | 0,089 | 0,094 | 0,102 |

| 2 | 1.0 x D1 | 110 | 120 | 125 | fz | 0,014 | 0,019 | 0,025 | 0,030 | 0,041 | 0,050 | 0,058 | 0,065 | 0,072 | 0,078 | 0,083 | 0,094 | |

| 3 | 1.0 x D1 | 110 | 115 | 120 | fz | 0,012 | 0,016 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 | |

| S | 1 | 0.75 x D1 | 50 | 60 | 70 | fz | 0,014 | 0,019 | 0,025 | 0,030 | 0,041 | 0,050 | 0,058 | 0,065 | 0,072 | 0,078 | 0,083 | 0,094 |

| 2 | 0.75 x D1 | 50 | 55 | 65 | fz | 0,012 | 0,016 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 | |

| 3 | 0.5 x D1 | 25 | 27 | 30 | fz | 0,008 | 0,010 | 0,013 | 0,016 | 0,022 | 0,026 | 0,031 | 0,035 | 0,038 | 0,042 | 0,045 | 0,051 | |

| 4 | 1.25 x D1 | 50 | 52 | 55 | fz | 0,009 | 0,013 | 0,017 | 0,021 | 0,030 | 0,037 | 0,043 | 0,048 | 0,053 | 0,057 | 0,061 | 0,069 | |

| H | 1 | 1.0 x D1 | 80 | 95 | 110 | fz | 0,013 | 0,018 | 0,022 | 0,027 | 0,037 | 0,045 | 0,051 | 0,058 | 0,063 | 0,068 | 0,073 | 0,080 |

| 2 | 1.0 x D1 | 70 | 80 | 90 | fz | 0,010 | 0,013 | 0,017 | 0,020 | 0,028 | 0,033 | 0,038 | 0,043 | 0,047 | 0,050 | 0,053 | 0,059 | |

| Helical Interpolation/Ramping | ||||||||||||||||||

|  | Recommended feed per tooth (fz = mm/z) for Helical Interpolation and Ramping | ||||||||||||||||

| WS15PE | Diameter | |||||||||||||||||

| Cutting Speed | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | |||||

| Material | Max Depth | min | Start | max | min-max | 3,5-5,7 | 4,6-7,6 | 5,8-9,5 | 6,9-11,4 | 9,2-15,2 | 11,5-19,0 | 13,8-22,8 | 16,1-26,6 | 18,4-30,4 | 20,7-34,2 | 23,0-38,0 | 28,8-47,5 | |

| P | 0 | 1.25 x D1 | 140 | 150 | 165 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,055 | 0,061 | 0,067 | 0,071 | 0,075 | 0,082 |

| 1 | 1.25 x D1 | 140 | 150 | 165 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,055 | 0,061 | 0,067 | 0,071 | 0,075 | 0,082 | |

| 2 | 1.25 x D1 | 140 | 150 | 165 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,055 | 0,061 | 0,067 | 0,071 | 0,075 | 0,082 | |

| 3 | 1.25 x D1 | 105 | 115 | 120 | fz | 0,011 | 0,015 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 | |

| 4 | 1.25 x D1 | 90 | 100 | 110 | fz | 0,011 | 0,014 | 0,018 | 0,022 | 0,030 | 0,036 | 0,041 | 0,046 | 0,051 | 0,055 | 0,058 | 0,064 | |

| 5 | 1.25 x D1 | 70 | 75 | 80 | fz | 0,009 | 0,013 | 0,016 | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,053 | 0,060 | |

| 6 | 1.25 x D1 | 55 | 60 | 65 | fz | 0,008 | 0,011 | 0,013 | 0,016 | 0,022 | 0,027 | 0,031 | 0,034 | 0,038 | 0,040 | 0,043 | 0,047 | |

| M | 1 | 1.25 x D1 | 75 | 85 | 90 | fz | 0,011 | 0,015 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 |

| 2 | 1.25 x D1 | 50 | 55 | 60 | fz | 0,009 | 0,013 | 0,016 | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,053 | 0,060 | |

| 3 | 1.0 x D1 | 45 | 50 | 55 | fz | 0,008 | 0,011 | 0,013 | 0,016 | 0,022 | 0,027 | 0,031 | 0,034 | 0,038 | 0,040 | 0,043 | 0,047 | |

| K | 1 | 1.0 x D1 | 110 | 120 | 130 | fz | 0,014 | 0,019 | 0,024 | 0,029 | 0,040 | 0,048 | 0,055 | 0,061 | 0,067 | 0,071 | 0,075 | 0,082 |

| 2 | 1.0 x D1 | 100 | 110 | 120 | fz | 0,011 | 0,015 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 | |

| 3 | 1.0 x D1 | 90 | 100 | 110 | fz | 0,009 | 0,013 | 0,016 | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,053 | 0,060 | |

| S | 1 | 0.75 x D1 | 80 | 85 | 90 | fz | 0,011 | 0,015 | 0,020 | 0,024 | 0,033 | 0,040 | 0,046 | 0,052 | 0,058 | 0,062 | 0,067 | 0,075 |

| 2 | 0.75 x D1 | 55 | 60 | 65 | fz | 0,009 | 0,013 | 0,016 | 0,019 | 0,026 | 0,032 | 0,037 | 0,042 | 0,046 | 0,050 | 0,053 | 0,060 | |

| 3 | 0.5 x D1 | 20 | 25 | 28 | fz | 0,006 | 0,008 | 0,011 | 0,013 | 0,017 | 0,021 | 0,025 | 0,028 | 0,031 | 0,033 | 0,036 | 0,040 | |

| 4 | 1.25 x D1 | 35 | 40 | 45 | fz | 0,008 | 0,010 | 0,014 | 0,017 | 0,024 | 0,029 | 0,034 | 0,038 | 0,042 | 0,046 | 0,049 | 0,055 | |

| H | 1 | 1.0 x D1 | 75 | 80 | 85 | fz | 0,011 | 0,014 | 0,018 | 0,022 | 0,030 | 0,036 | 0,041 | 0,046 | 0,051 | 0,055 | 0,058 | 0,064 |

| 2 | 1.0 x D1 | 65 | 70 | 75 | fz | 0,008 | 0,011 | 0,013 | 0,016 | 0,022 | 0,027 | 0,031 | 0,034 | 0,038 | 0,040 | 0,043 | 0,047 | |

| Plunging | ||||||||||||||||||||

|  | WS15PE | Recommended feed per revolution (fn =mm/rev) for plunging and drilling | |||||||||||||||||

| Cutting Speed | D1 | |||||||||||||||||||

| Material | Max Depth | Applicable | Coolant | min | Start | max | mm | 3,0 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | |

| P | 0 | 1,25 x D1 | Preferred | 140 | 150 | 165 | fn | 0,033 | 0,040 | 0,045 | 0,055 | 0,065 | 0,080 | 0,095 | 0,110 | 0,120 | 0,140 | 0,160 | 0,180 | |

| 1 | 1,25 x D1 | Required | 140 | 150 | 165 | fn | 0,033 | 0,040 | 0,045 | 0,055 | 0,065 | 0,080 | 0,095 | 0,110 | 0,120 | 0,140 | 0,160 | 0,180 | ||

| 2 | 1,25 x D1 | Required | 140 | 150 | 165 | fn | 0,033 | 0,040 | 0,045 | 0,055 | 0,065 | 0,080 | 0,095 | 0,110 | 0,120 | 0,140 | 0,160 | 0,180 | ||

| 3 | 1,25 x D1 | Required | 105 | 115 | 120 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | ||

| 4 | 1,25 x D1 | Required | 90 | 100 | 110 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | ||

| 5 | 1,25 x D1 | Required | 70 | 75 | 80 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| 6 | 1,25 x D1 | Required | 55 | 60 | 65 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| M | 1 | 1,25 x D1 | Required | 75 | 85 | 90 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | |

| 2 | 1,25 x D1 | Required | 50 | 55 | 60 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| 3 | 1,0 x D1 | Required | 45 | 50 | 55 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| K | 1 | 1,0 x D1 | Preferred | 110 | 120 | 130 | fn | 0,033 | 0,040 | 0,045 | 0,055 | 0,065 | 0,080 | 0,095 | 0,110 | 0,120 | 0,140 | 0,160 | 0,180 | |

| 2 | 1,0 x D1 | Required | 100 | 110 | 120 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | ||

| 3 | 1,0 x D1 | Required | 90 | 100 | 110 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | ||

| S | 1 | 0,75 x D1 | Required | 80 | 85 | 90 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | |

| 2 | 0,75 x D1 | Required | 55 | 60 | 65 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| 3 | 0,5 x D1 | Required | 20 | 25 | 28 | fn | 0,010 | 0,012 | 0,015 | 0,018 | 0,022 | 0,028 | 0,033 | 0,040 | 0,045 | 0,050 | 0,060 | 0,070 | ||

| 4 | 1,25 x D1 | Required | 35 | 40 | 45 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| H | 1 | 1,0 x D1 | Required | 75 | 80 | 85 | fn | 0,020 | 0,028 | 0,033 | 0,040 | 0,050 | 0,060 | 0,070 | 0,085 | 0,100 | 0,110 | 0,125 | 0,150 | |

| 2 | 1,0 x D1 | Required | 65 | 70 | 75 | fn | 0,014 | 0,018 | 0,020 | 0,025 | 0,035 | 0,040 | 0,050 | 0,055 | 0,065 | 0,075 | 0,085 | 0,100 | ||

| Material |  |  |  | ||||||||||||||

| Side Milling (A) and Slotting (B) | WS15PE | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||

| A | B | Cutting Speed | D1 | ||||||||||||||

| ap | ae | ap | Min | Start | Max | in | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||

| P | 0 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | 580 | 660 | IPT | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 |

| 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | 580 | 660 | IPT | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 | |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 460 | 540 | 620 | IPT | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 390 | 450 | 520 | IPT | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | 400 | 490 | IPT | .0007 | .0012 | .0014 | .0019 | .0023 | .0027 | .0033 | .0038 | .0042 | |

| 5 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | 260 | 330 | IPT | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| 6 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | 200 | 250 | IPT | .0005 | .0009 | .0011 | .0015 | .0017 | .0020 | .0025 | .0028 | .0031 | |

| M | 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | 340 | 380 | IPT | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | 230 | 260 | IPT | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 200 | 210 | 230 | IPT | .0005 | .0009 | .0011 | .0015 | .0017 | .0020 | .0025 | .0028 | .0031 | |

| K | 1 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 390 | 440 | 490 | IPT | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 360 | 410 | 460 | IPT | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 360 | 390 | 430 | IPT | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| S | 1 | 1.5 x D1 | 0.5 x D1 | 0.75 x D1 | 160 | 230 | 300 | IPT | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 |

| 2 | 1.5 x D1 | 0.5 x D1 | 0.75 x D1 | 160 | 210 | 260 | IPT | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 0.5 x D1 | 80 | 100 | 130 | IPT | .0004 | .0007 | .0008 | .0011 | .0014 | .0016 | .0020 | .0023 | .0027 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | 180 | 200 | IPT | .0005 | .0009 | .0011 | .0016 | .0019 | .0022 | .0028 | .0032 | .0036 | |

| H | 1 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 260 | 360 | 460 | IPT | .0007 | .0012 | .0014 | .0019 | .0023 | .0027 | .0033 | .0038 | .0042 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.0 x D1 | 230 | 310 | 390 | IPT | .0005 | .0009 | .0011 | .0015 | .0017 | .0020 | .0025 | .0028 | .0031 | |

| NOTE: See page XX for more information on VARIMILL™ XTREME™ adjustment factors for feed calculations. | |||||||||||||||||

| Helical Interpolation/Ramping | |||||||||||||||

|  | Recommended feed per tooth (fz = IPT) for Helical Interpolation and Ramping | |||||||||||||

| WS15PE | Diameter | ||||||||||||||

| Cutting Speed | in | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||

| Material | Max Depth | min | Start | max | min-max | .144 - .238 | .216 - .356 | .288 - .475 | .359 - .594 | .431 - .713 | .575 - 950 | .719 - 1.188 | .863 - 1.425 | 1.150 - 1.900 | |

| P | 0 | 1.25 x D1 | 490 | 530 | 580 | fz | .0007 | .0012 | .0014 | .0020 | .0023 | .0027 | .0033 | .0037 | .0041 |

| 1 | 1.25 x D1 | 490 | 530 | 580 | fz | .0007 | .0012 | .0014 | .0020 | .0023 | .0027 | .0033 | .0037 | .0041 | |

| 2 | 1.25 x D1 | 460 | 500 | 540 | fz | .0007 | .0012 | .0014 | .0020 | .0023 | .0027 | .0033 | .0037 | .0041 | |

| 3 | 1.25 x D1 | 390 | 420 | 450 | fz | .0005 | .0010 | .0012 | .0017 | .0020 | .0023 | .0029 | .0033 | .0037 | |

| 4 | 1.25 x D1 | 300 | 350 | 400 | fz | .0005 | .0009 | .0011 | .0014 | .0017 | .0020 | .0025 | .0029 | .0032 | |

| 5 | 1.25 x D1 | 200 | 235 | 260 | fz | .0005 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 | |

| 6 | 1.25 x D1 | 160 | 180 | 200 | fz | .0004 | .0007 | .0008 | .0011 | .0013 | .0015 | .0019 | .0021 | .0023 | |

| M | 1 | 1.25 x D1 | 300 | 320 | 340 | fz | .0005 | .0010 | .0012 | .0017 | .0020 | .0023 | .0029 | .0033 | .0037 |

| 2 | 1.25 x D1 | 200 | 215 | 230 | fz | .0005 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 | |

| 3 | 1.0 x D1 | 200 | 105 | 210 | fz | .0004 | .0007 | .0008 | .0011 | .0013 | .0015 | .0019 | .0021 | .0023 | |

| K | 1 | 1.0 x D1 | 390 | 415 | 440 | fz | .0007 | .0012 | .0014 | .0020 | .0023 | .0027 | .0033 | .0037 | .0041 |

| 2 | 1.0 x D1 | 360 | 380 | 410 | fz | .0005 | .0010 | .0012 | .0017 | .0020 | .0023 | .0029 | .0033 | .0037 | |

| 3 | 1.0 x D1 | 360 | 375 | 390 | fz | .0005 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 | |

| S | 1 | 0.75 x D1 | 160 | 190 | 230 | fz | .0005 | .0010 | .0012 | .0017 | .0020 | .0023 | .0029 | .0033 | .0037 |

| 2 | 0.75 x D1 | 160 | 180 | 210 | fz | .0005 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 | |

| 3 | 0.5 x D1 | 80 | 90 | 100 | fz | .0003 | .0005 | .0006 | .0008 | .0011 | .0012 | .0015 | .0017 | .002 | |

| 4 | 1.25 x D1 | 160 | 170 | 180 | fz | .0004 | .0007 | .0008 | .0012 | .0014 | .0017 | .0021 | .0024 | .0027 | |

| H | 1 | 1.0 x D1 | 260 | 310 | 360 | fz | .0005 | .0009 | .0011 | .0014 | .0017 | .0020 | .0025 | .0029 | .0032 |

| 2 | 1.0 x D1 | 230 | 270 | 310 | fz | .0004 | .0007 | .0008 | .0011 | .0013 | .0015 | .0019 | .0021 | .0023 | |

| Helical Interpolation/Ramping | |||||||||||||||

|  | Recommended feed per tooth (fz = IPT) for Helical Interpolation and Ramping | |||||||||||||

| WS15PE | Diameter | ||||||||||||||

| Cutting Speed | in | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||

| Material | Max Depth | min | Start | max | min-max | .144 - .238 | .216 - .356 | .288 - .475 | .359 - .594 | .431 - .713 | .575 - 950 | .719 - 1.188 | .863 - 1.425 | 1.150 - 1.900 | |

| P | 0 | 1.25 x D1 | 490 | 580 | 660 | fz | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 |

| 1 | 1.25 x D1 | 490 | 580 | 660 | fz | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 | |

| 2 | 1.25 x D1 | 460 | 540 | 620 | fz | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 | |

| 3 | 1.25 x D1 | 390 | 450 | 520 | fz | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 | |

| 4 | 1.25 x D1 | 300 | 400 | 490 | fz | .0007 | .0012 | .0014 | .0019 | .0023 | .0027 | .0033 | .0038 | .0042 | |

| 5 | 1.25 x D1 | 200 | 260 | 330 | fz | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| 6 | 1.25 x D1 | 160 | 200 | 250 | fz | .0005 | .0009 | .0011 | .0015 | .0017 | .0020 | .0025 | .0028 | .0031 | |

| M | 1 | 1.25 x D1 | 300 | 340 | 380 | fz | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 |

| 2 | 1.25 x D1 | 200 | 230 | 260 | fz | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| 3 | 1.0 x D1 | 200 | 210 | 230 | fz | .0005 | .0009 | .0011 | .0015 | .0017 | .0020 | .0025 | .0028 | .0031 | |

| K | 1 | 1.0 x D1 | 390 | 440 | 490 | fz | .0009 | .0016 | .0019 | .0026 | .0031 | .0036 | .0044 | .0049 | .0054 |

| 2 | 1.0 x D1 | 360 | 410 | 460 | fz | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 | |

| 3 | 1.0 x D1 | 360 | 390 | 430 | fz | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| S | 1 | 0.75 x D1 | 160 | 230 | 300 | fz | .0007 | .0013 | .0016 | .0022 | .0026 | .0030 | .0038 | .0044 | .0049 |

| 2 | 0.75 x D1 | 160 | 210 | 260 | fz | .0006 | .0011 | .0013 | .0017 | .0021 | .0024 | .0030 | .0035 | .0039 | |

| 3 | 0.5 x D1 | 80 | 100 | 130 | fz | .0004 | .0007 | .0008 | .0011 | .0014 | .0016 | .0020 | .0023 | .0027 | |

| 4 | 1.25 x D1 | 160 | 180 | 200 | fz | .0005 | .0009 | .0011 | .0016 | .0019 | .0022 | .0028 | .0032 | .0036 | |

| H | 1 | 1.0 x D1 | 260 | 360 | 460 | fz | .0007 | .0012 | .0014 | .0019 | .0023 | .0027 | .0033 | .0038 | .0042 |

| 2 | 1.0 x D1 | 230 | 310 | 390 | fz | .0005 | .0009 | .0011 | .0015 | .0017 | .0020 | .0025 | .0028 | .0031 | |

| Helical Interpolation/Ramping | |||||||||||||||

|  | Recommended feed per tooth (fz = IPT) for Helical Interpolation and Ramping | |||||||||||||

| WS15PE | Diameter | ||||||||||||||

| Cutting Speed | in | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||

| Material | Max Depth | min | Start | max | min-max | .144 - .238 | .216 - .356 | .288 - .475 | .359 - .594 | .431 - .713 | .575 - 950 | .719 - 1.188 | .863 - 1.425 | 1.150 - 1.900 | |

| P | 0 | 1.25 x D1 | 420 | 450 | 495 | fz | .0005 | .0010 | .0011 | .0016 | .0019 | .0022 | .0026 | .0029 | .0032 |

| 1 | 1.25 x D1 | 420 | 450 | 495 | fz | .0005 | .0010 | .0011 | .0016 | .0019 | .0022 | .0026 | .0029 | .0032 | |

| 2 | 1.25 x D1 | 420 | 450 | 495 | fz | .0005 | .0010 | .0011 | .0016 | .0019 | .0022 | .0026 | .0029 | .0032 | |

| 3 | 1.25 x D1 | 315 | 345 | 360 | fz | .0004 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 | |

| 4 | 1.25 x D1 | 270 | 300 | 330 | fz | .0004 | .0007 | .0008 | .0011 | .0014 | .0016 | .0020 | .0023 | .0025 | |

| 5 | 1.25 x D1 | 210 | 225 | 240 | fz | .0004 | .0007 | .0008 | .0010 | .0013 | .0014 | .0018 | .0021 | .0023 | |

| 6 | 1.25 x D1 | 165 | 180 | 195 | fz | .0003 | .0005 | .0007 | .0009 | .0010 | .0012 | .0015 | .0017 | .0019 | |

| M | 1 | 1.25 x D1 | 225 | 255 | 270 | fz | .0004 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 |

| 2 | 1.25 x D1 | 150 | 165 | 180 | fz | .0004 | .0007 | .0008 | .0010 | .0013 | .0014 | .0018 | .0021 | .0023 | |

| 3 | 1.0 x D1 | 135 | 150 | 165 | fz | .0003 | .0005 | .0007 | .0009 | .0010 | .0012 | .0015 | .0017 | .0019 | |

| K | 1 | 1.0 x D1 | 330 | 360 | 390 | fz | .0005 | .0010 | .0011 | .0016 | .0019 | .0022 | .0026 | .0029 | .0032 |

| 2 | 1.0 x D1 | 300 | 330 | 360 | fz | .0004 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 | |

| 3 | 1.0 x D1 | 270 | 300 | 330 | fz | .0004 | .0007 | .0008 | .0010 | .0013 | .0014 | .0018 | .0021 | .0023 | |

| S | 1 | 0.75 x D1 | 240 | 255 | 270 | fz | .0004 | .0008 | .0010 | .0013 | .0016 | .0018 | .0023 | .0026 | .0029 |

| 2 | 0.75 x D1 | 165 | 180 | 195 | fz | .0004 | .0007 | .0008 | .0010 | .0013 | .0014 | .0018 | .0021 | .0023 | |

| 3 | 0.5 x D1 | 60 | 75 | 84 | fz | .0002 | .0004 | .0005 | .0007 | .0008 | .0010 | .0012 | .0014 | .0016 | |

| 4 | 1.25 x D1 | 105 | 120 | 135 | fz | .0003 | .0005 | .0007 | .0010 | .0011 | .0013 | .0017 | .0019 | .0022 | |

| H | 1 | 1.0 x D1 | 225 | 240 | 255 | fz | .0004 | .0007 | .0008 | .0011 | .0014 | .0016 | .0020 | .0023 | .0025 |

| 2 | 1.0 x D1 | 195 | 210 | 225 | fz | .0003 | .0005 | .0007 | .0009 | .0010 | .0012 | .0015 | .0017 | .0019 | |

| Plunging | |||||||||||||||||

|  | WS15PE | Recommended feed per revolution (fn =mm/rev) for plunging and drilling | ||||||||||||||

| Cutting Speed | D1 | ||||||||||||||||

| Material | Max Depth | Applicable | Coolant | min | Start | max | in | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |

| P | 0 | 1,25 x D1 | Preferred | 420 | 450 | 495 | IPR | .0013 | 0.0018 | .0022 | .0026 | .0031 | .0037 | .0047 | .0063 | .0071 | |

| 1 | 1,25 x D1 | Required | 420 | 450 | 495 | IPR | .0013 | 0.0018 | .0022 | .0026 | .0031 | .0037 | .0047 | .0063 | .0071 | ||

| 2 | 1,25 x D1 | Required | 420 | 450 | 495 | IPR | .0013 | 0.0018 | .0022 | .0026 | .0031 | .0037 | .0047 | .0063 | .0071 | ||

| 3 | 1,25 x D1 | Required | 315 | 345 | 360 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .0039 | .0049 | .0059 | ||

| 4 | 1,25 x D1 | Required | 270 | 300 | 330 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .0039 | .0049 | .0059 | ||

| 5 | 1,25 x D1 | Required | 210 | 225 | 240 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

| 6 | 1,25 x D1 | Required | 165 | 180 | 195 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

| M | 1 | 1,25 x D1 | Required | 225 | 255 | 270 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .00239 | .0049 | .0059 | |

| 2 | 1,25 x D1 | Required | 150 | 165 | 180 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

| 3 | 1,0 x D1 | Required | 135 | 150 | 165 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

| K | 1 | 1,0 x D1 | Preferred | 330 | 360 | 390 | IPR | .0013 | 0.0018 | .0022 | .0026 | .0031 | .0037 | .0047 | .0063 | .0071 | |

| 2 | 1,0 x D1 | Required | 300 | 330 | 360 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .0039 | .0049 | .0059 | ||

| 3 | 1,0 x D1 | Required | 270 | 300 | 330 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .0039 | .0049 | .0059 | ||

| S | 1 | 0,75 x D1 | Required | 240 | 255 | 270 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .0039 | .0049 | .0059 | |

| 2 | 0,75 x D1 | Required | 165 | 180 | 195 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

| 3 | 0,5 x D1 | Required | 60 | 75 | 84 | IPR | .0004 | 0.0006 | .0007 | .0009 | .0011 | .0013 | .0018 | .0024 | .0028 | ||

| 4 | 1,25 x D1 | Required | 105 | 120 | 135 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

| H | 1 | 1,0 x D1 | Required | 225 | 240 | 255 | IPR | .0008 | 0.0013 | .0016 | .0020 | .0024 | .0028 | .0039 | .0049 | .0059 | |

| 2 | 1,0 x D1 | Required | 195 | 210 | 225 | IPR | .0006 | 0.0008 | .0010 | .0014 | .0016 | .0020 | .0026 | .0033 | .0039 | ||

I have read and accepted the Terms & Conditions of use