Product Similar To:

X-Feed™ • Series 70N7 • >52 HRC • High Feed • 6 Flute • Cylindrical Shank • Metric

Series 70N7 • Hard Materials • Metric

Material Number3484758

ISO Catalog ID70N710004MTANSI Catalog ID70N710004MT

- H Hardened Materials

Ramping: Blank

Shank - Cylindrical Plain

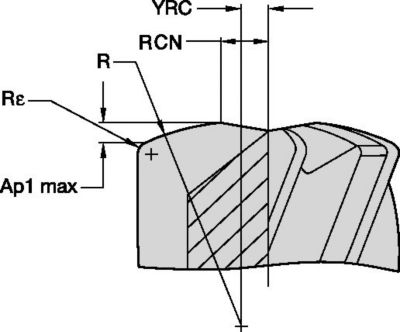

Corner Style: Torus

Helix Angle: 20°

Tool Dimensions: Flute Configuration: 6

3D Profiling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3484758 |

| ISO Catalog ID | 70N710004MT |

| ANSI Catalog ID | 70N710004MT |

| Grade | ALTIN-MT1 |

| Adapter Style Machine Side | Straight-Cylindrical |

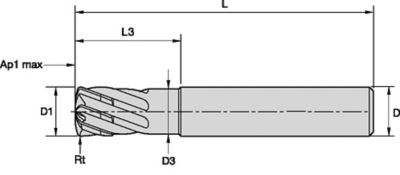

| [D1] Effective Cutting Diameter | 10 mm |

| [D1] Effective Cutting Diameter | 0.394 in |

| [D] Adapter / Shank / Bore Diameter | 10 mm |

| [D] Adapter / Shank / Bore Diameter | 0.3937 in |

| [D3] Neck Diameter | 9 mm |

| [D3] Neck Diameter | 0.354 in |

| [AP1MAX] 1st Maximum Cutting Depth | 0.33 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.013 in |

| [L3] Usable Length | 30 mm |

| [L3] Usable Length | 1.181 in |

| [L] Overall Length | 89 mm |

| [L] Overall Length | 3.5039 in |

| [Re] Corner Radius | 0.625 mm |

| [Re] Corner Radius | 0.025 in |

| Theoretical Cor Rad Prog I [RT] | 0.96 mm |

| Theoretical Cor Rad Prog I [RT] | 0.0378 in |

| [Z] Number of Flutes | 6 |

Workpiece Materials

- Hardened Materials

Uses and application

Ramping: Blank

Shank - Cylindrical Plain

Corner Style: Torus

Helix Angle: 20°

Tool Dimensions: Flute Configuration: 6

3D Profiling

Features and benefits

- Non-center cutting.

- Standard items listed. Additional styles and coatings made to order.

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Application Data

Application Data • Series 70N7 • Hard Materials • Metric

| Tool List 70N7 | |||||||||||||||

| Geometrical Parameters | Ramping Guide for Circular and Linear Interpolation | ||||||||||||||

| Circular Interpolation | Linear Interpolation | ||||||||||||||

| Allowed Range of Hole Diameter | Calculated Length (mm) per Ramp Angle | ||||||||||||||

| diameter | Ap1 max | Rfm | Rt | Rc | Xfm | Yfm | YD | Number | Ramp Angle (degree) | ||||||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | flutes | Smallest | Largest | 1 | 2 | 3 | 4 | 5 |

| 6 | 0,20 | 9 | 0,58 | 0,375 | 0,20 | 0,75 | 1,26 | 6 | 8,52 | 12 | 11,51 | 5,75 | 3,83 | 2,87 | 2,30 |

| 8 | 0,27 | 12 | 0,77 | 0,500 | 0,27 | 1,00 | 1,68 | 6 | 11,36 | 16 | 15,34 | 7,67 | 5,11 | 3,83 | 3,06 |

| 10 | 0,33 | 15 | 0,96 | 0,625 | 0,33 | 1,25 | 2,10 | 6 | 14,2 | 20 | 19,18 | 9,58 | 6,39 | 4,79 | 3,83 |

| 12 | 0,40 | 18 | 1,15 | 0,750 | 0,40 | 1,50 | 2,52 | 6 | 17,04 | 24 | 23,01 | 11,50 | 7,66 | 5,74 | 4,59 |

| 16 | 0,54 | 24 | 1,54 | 1,000 | 0,54 | 2,00 | 3,36 | 6 | 22,72 | 32 | 30,68 | 15,34 | 10,22 | 7,66 | 6,12 |

| 20 | 0,67 | 30 | 1,92 | 1,250 | 0,67 | 2,50 | 4,20 | 6 | 28,4 | 40 | 38,35 | 19,17 | 12,77 | 9,57 | 7,65 |

| Recommended Feed | 100% | 70% | 50% | 30% | 10% | ||||||||||

Programming Data

|  | ||||||||||||

| Profile Milling | AlTiN | Recommended feed per tooth (fz = mm/th) for 3D milling/profiling (A) | |||||||||||

| A | Cutting Speed | D1 | |||||||||||

| Material | ap | ae | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| H | 2 | 0,03 x D | 0,55 x D | 100 | – | 120 | fz | 0,200 | 0,300 | 0,300 | 0,400 | 0,500 | 0,600 |

| 3 | 0,03 x D | 0,55 x D | 80 | – | 100 | fz | 0,200 | 0,300 | 0,300 | 0,400 | 0,500 | 0,600 | |

| 4 | 0,03 x D | 0,55 x D | 50 | – | 70 | fz | 0,150 | 0,200 | 0,250 | 0,300 | 0,400 | 0,500 | |

I have read and accepted the Terms & Conditions of use