Product Similar To:

VHSC • Shell Mills • Inch

Shell Mills • Inch

Material Number6425433

ISO Catalog IDVHSC400Z05S125XD16ANSI Catalog IDVHSC400Z05S125XD16

- K Cast Iron

- N Non-Ferrous

- .caption

Face Milling

Helical Milling

Ramping: Blank

Milling - Through Coolant

Milling - Side and Face

Pocketing

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6425433 |

| ISO Catalog ID | VHSC400Z05S125XD16 |

| ANSI Catalog ID | VHSC400Z05S125XD16 |

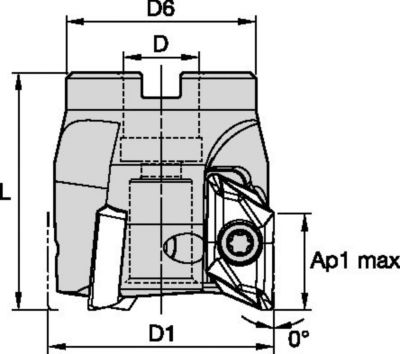

| [D1] Effective Cutting Diameter | 101.6 mm |

| [D1] Effective Cutting Diameter | 4 in |

| [D] Adapter / Shank / Bore Diameter | 31.75 mm |

| [D] Adapter / Shank / Bore Diameter | 1.25 in |

| [D6] Hub Diameter | 62 mm |

| [D6] Hub Diameter | 2.4409 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.9685 in |

| [AP1MAX] 1st Maximum Cutting Depth | 16 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.6299 in |

| Number of Inserts | 5 |

| Maximum Ramping Angle | 3.7 |

| Max RPM | 23000 |

| Coolant Supply | Y |

| Weight Pounds | 3.51 |

Workpiece Materials

- Cast Iron

- Non-Ferrous

- .caption

Uses and application

Face Milling

Helical Milling

Ramping: Blank

Milling - Through Coolant

Milling - Side and Face

Pocketing

Inclined Square End Mill

Features and benefits

- Productivity booster up to 525in3/min (8600cm3/min) MRR at machining Aluminum components.

- Only one cutter body style to load inserts with nose radii from .008" (0.2mm) up to .236" (6mm).

- Consistent axial gage length with insert nose radii from .008" (0.2mm) up to .236" (6mm).

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | 0,12 | 0,45 | 0,81 | 0,08 | 0,33 | 0,58 | 0,06 | 0,25 | 0,43 | 0,06 | 0,21 | 0,38 | 0,05 | 0,20 | 0,35 | .F..ALP |

| .E..ALP | 0,15 | 0,50 | 0,92 | 0,11 | 0,36 | 0,66 | 0,08 | 0,27 | 0,50 | 0,07 | 0,24 | 0,43 | 0,07 | 0,22 | 0,40 | .E..ALP |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .F..ALP | .005 | .018 | .032 | .003 | .013 | .023 | .003 | .010 | .017 | .002 | .009 | .015 | .002 | .008 | .014 | .F..ALP |

| .E..ALP | .006 | .020 | .037 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .017 | .003 | .009 | .016 | .E..ALP |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds For Wet Machining [m/min]

| Material Group | WN10HM | |||

| N | 1 | 2950 | 1800 | 875 |

| 2 | 2950 | 1800 | 875 | |

| 3 | 1600 | 850 | 480 | |

Recommended Starting Speeds for Wet Machining [SFM]

| Material Group | WN10HM | |||

| N | 1 | 9640 | 5880 | 2860 |

| 2 | 9640 | 5880 | 2860 | |

| 3 | 5230 | 2775 | 1565 | |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| N1–N2 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

| N3 | .F..ALP | WN10HM | .F..ALP | WN10HM | .E..ALP | WN10HM |

I have read and accepted the Terms & Conditions of use