Product Similar To:

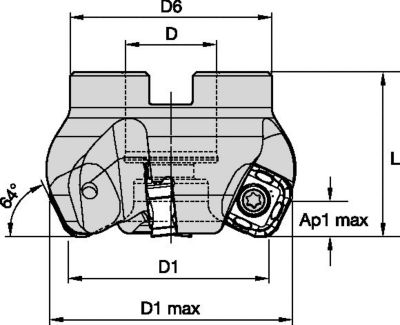

M8065HD • 64° • Shell Mills • Metric

M8065HD • Shell Mills • Heavy-Duty Face Milling

Material Number4073640

ISO Catalog IDM8065HD100Z07S32SN15ANSI Catalog IDM8065HD100Z07S32SN15

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Face Milling

Side Milling/Shoulder Milling: Eased Chamfer

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 4073640 |

| ISO Catalog ID | M8065HD100Z07S32SN15 |

| ANSI Catalog ID | M8065HD100Z07S32SN15 |

| [D1] Effective Cutting Diameter | 100 mm |

| [D1] Effective Cutting Diameter | 3.937 in |

| [D1MAX] Maximum Cutting Diameter | 108.836 mm |

| [D1MAX] Maximum Cutting Diameter | 4.2849 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.2598 in |

| [D6] Hub Diameter | 78 mm |

| [D6] Hub Diameter | 3.0709 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.9685 in |

| [L1] Gage Length | 50 mm |

| [L1] Gage Length | 1.9685 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.3543 in |

| Number of Inserts | 7 |

| Coolant Supply | N |

| Weight Kilograms | 1.68 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Face Milling

Side Milling/Shoulder Milling: Eased Chamfer

Features and benefits

- 16.5° lead angle redistributes cutting forces in the spindle z-axis direction

- Greatly reduces tool defl ection and vibrations for improved tool life

- Suitable for long tool reach

- Unique integrated radial wiping facet to achieve a nice wall finish at pocket and helical interpolation milling

- Durable cutting edges qualifi ed to machine a wide range of materials

- WS40PM — best-in-class milling grade for machining stainless steel and HTA

Create Solution to calculate Feeds and Speed

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders. Do you want to learn more? Watch Tutorial

Feeds

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .S..MM | 0,22 | 0,65 | 1,07 | 0,16 | 0,47 | 0,77 | 0,12 | 0,35 | 0,58 | 0,10 | 0,31 | 0,50 | 0,10 | 0,28 | 0,46 | .S..MM |

| .S..MH | 0,24 | 0,71 | 1,17 | 0,17 | 0,51 | 0,84 | 0,13 | 0,38 | 0,63 | 0,11 | 0,34 | 0,55 | 0,11 | 0,30 | 0,50 | .S..MH |

| Light | General | Heavy |

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40-100% | ||||||||||||

| .S..MM | .008 | .026 | .042 | .006 | .018 | .030 | .005 | .014 | .023 | .004 | .012 | .020 | .004 | .011 | .018 | .S..MM |

| .S..MH | .009 | .028 | .046 | .007 | .020 | .033 | .005 | .015 | .025 | .004 | .013 | .022 | .004 | .012 | .020 | .S..MH |

| Light | General | Heavy |

Speeds

| Material Group | WP35CM | WK15CM | WU20PM | |||||||

| P | 1 | 455 | 395 | 370 | — | — | — | 330 | 290 | 270 |

| 2 | 280 | 255 | 230 | — | — | — | 275 | 250 | 200 | |

| 3 | 255 | 230 | 205 | — | — | — | 255 | 220 | 175 | |

| 4 | 190 | 175 | 160 | — | — | — | 225 | 190 | 150 | |

| 5 | 260 | 230 | 210 | — | — | — | 185 | 175 | 150 | |

| 6 | 160 | 135 | — | — | — | — | 165 | 130 | 100 | |

| M | 1 | 205 | 185 | 155 | — | — | — | 205 | 180 | 165 |

| 2 | 185 | 160 | 140 | — | — | — | 185 | 160 | 130 | |

| 3 | 145 | 130 | 115 | — | — | — | 140 | 120 | 95 | |

| K | 1 | 295 | 265 | 240 | 420 | 385 | 340 | 250 | 220 | 185 |

| 2 | 235 | 210 | 190 | 335 | 295 | 275 | 200 | 180 | 150 | |

| 3 | 195 | 175 | 160 | 280 | 250 | 230 | 180 | 150 | 120 | |

| N | 1 | — | — | — | — | — | — | 550 | 470 | 400 |

| 2 | — | — | — | — | — | — | 550 | 470 | 400 | |

| 3 | — | — | — | — | — | — | 400 | 350 | 300 | |

| S | 1 | — | — | — | — | — | — | 40 | 35 | 25 |

| 2 | — | — | — | — | — | — | 40 | 35 | 25 | |

| 3 | — | — | — | — | — | — | 50 | 40 | 25 | |

| 4 | — | — | — | — | — | — | 70 | 50 | 35 | |

| H | 1 | — | — | — | — | — | — | 110 | 80 | 70 |

| Material Group | WP35CM | WK15CM | WU20PM | |||||||

| P | 1 | 1490 | 1300 | 1210 | — | — | — | 1080 | 950 | 890 |

| 2 | 920 | 840 | 750 | — | — | — | 900 | 820 | 660 | |

| 3 | 840 | 750 | 670 | — | — | — | 840 | 720 | 570 | |

| 4 | 620 | 570 | 520 | — | — | — | 740 | 620 | 490 | |

| 5 | 850 | 750 | 690 | — | — | — | 610 | 570 | 490 | |

| 6 | 520 | 440 | — | — | — | — | 540 | 430 | 330 | |

| M | 1 | 670 | 610 | 510 | — | — | — | 670 | 590 | 540 |

| 2 | 610 | 520 | 460 | — | — | — | 610 | 520 | 430 | |

| 3 | 480 | 430 | 380 | — | — | — | 460 | 390 | 310 | |

| K | 1 | 970 | 870 | 790 | 1380 | 1260 | 1120 | 820 | 720 | 610 |

| 2 | 770 | 690 | 620 | 1100 | 970 | 900 | 660 | 590 | 490 | |

| 3 | 640 | 570 | 520 | 920 | 820 | 750 | 590 | 490 | 390 | |

| N | 1 | — | — | — | — | — | — | 1800 | 1540 | 1310 |

| 2 | — | — | — | — | — | — | 1800 | 1540 | 1310 | |

| 3 | — | — | — | — | — | — | 1310 | 1150 | 980 | |

| S | 1 | — | — | — | — | — | — | 130 | 110 | 80 |

| 2 | — | — | — | — | — | — | 130 | 110 | 80 | |

| 3 | — | — | — | — | — | — | 160 | 130 | 80 | |

| 4 | — | — | — | — | — | — | 230 | 160 | 110 | |

| H | 1 | — | — | — | — | — | — | 360 | 260 | 230 |

Insert Selection

Insert Selection Guide

| Light | General | Heavy | ||||

| Material | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WU20PM |

| P3–P4 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WU20PM |

| P5–P6 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WP35CM |

| M1–M2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| M3 | .S..MM | WP35CM | .S..MM | WP35CM | .S..MM | WP35CM |

| K1–K2 | .S..MM | WK15CM | .S..MM | WK15CM | .S..MM | WU20PM |

| K3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WK15CM |

| N1–N2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| N3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S1–S2 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S3 | .S..MM | WU20PM | .S..MM | WU20PM | .S..MM | WU20PM |

| S4 | .S..MM | WP35CM | .S..MM | WU20PM | .S..MM | WU20PM |

I have read and accepted the Terms & Conditions of use